Have a 20 month old furler which up until recently has worked very well.

Lately the line has not been rolling up correctly on the drum and when I go to furl the sail in the line fouls. When I check it the line has come off the bottom of the drum. Is the line too thick or has the salt made it stiff and caused problems with it coiling on the drum.

I could'nt find anything in the manual although I did see where I am supposed to put some grease every 12 months for maintenance. What grease is best?

thx in advance

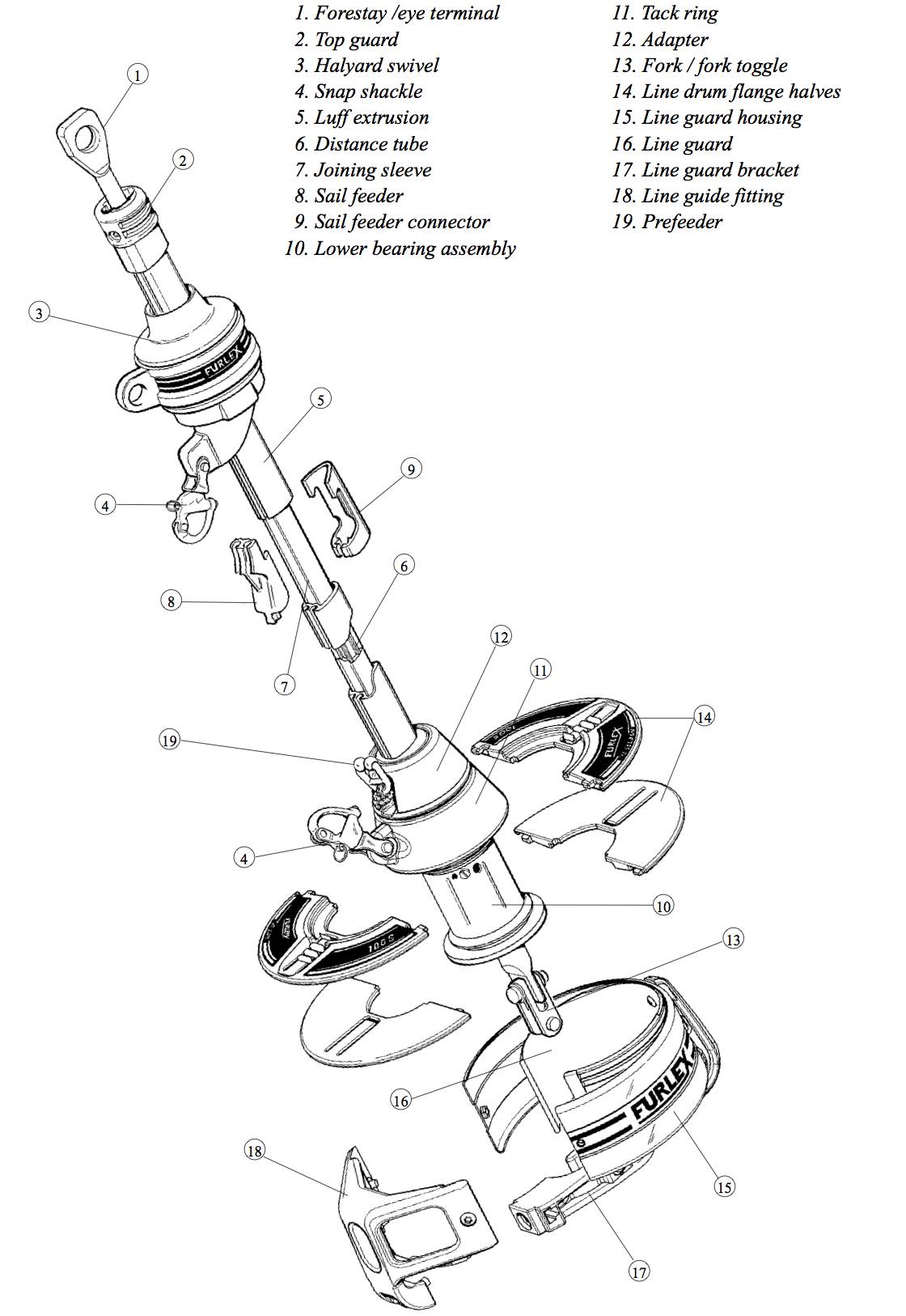

Actually I just looked at the exploded view (see below) and wonder if the bottom two "line drum flange halves" (no. 14) have come off and been lost overboard at some point and this is why the line ends up coiled up below the lower bearing assembly?

Have you tried getting someone to furl/unfurl it while you are on the foredeck looking at the furler and watch what happens as the line enters the furler

I have never had one of these apart but looking at the picture and your photo I think that the 14's on top are there (they have the Furlex name on them and it should be obvious if the lowers are there as well

The line guard (no 16) appears to wrap around the drum and expand and contract as the line comes on to and leaves the drum to prevent the line from falling of the top or bottom of the drum and I am wondering if it is stuck in the expanded position and not doing its job

It is a simple looking bit of gear so if you watch what is happening as it curls and unfurls it should be fairly obvious what is wrong

On page 47 of this www.seldenmast.com/files/1408026206/595-102-E.pdf it shows you how to remove the covers

Regards Don

I used to have the same problem. Dropped the line size down to 5mm and problem went away.

When deploying the headsail keep some weight on the furling line and cleat it off so that there is very little slack on the drum. When furling keep some tension on the sheets and only furl with hand power. I use a dinghy ratchet block as a turning block. Naturally when leaving the boat make sure you have 3 or 4 wraps of the sheet over the furled sail and the furling line properly cleated off.

I have an older model Furlex with the protruding fairlead. The "line guard housing"(15) around the drum has been removed to allow more furling line for the sail. Now there is nothing to stop loops of rope falling off the drum and wrapping around the stay, this happens when unfurling the jib and not enough tension is applied to the furling line or the line has become simply just slack when the sail is out, it becomes a real pain in the butt.

I found the removed housing in the boat so its going back on and I will do what furlex suggest and remove the first few feet/ meter of inner core of the furling line (drum end) to reduce the coiled rope diameter

Unless you have a 60ft boat I tend to agree with Ramona that the line is too big. I use 8mm on my boat and it holds well half furled in 40 kts.

thx for the info gents!

I will check things out again and will most probably drop the line size

If it has been working for 20 months with that size of line on it reducing the line size should not be necessary to make it work again

I would be looking to see what the actual cause is and as I said earlier it is a fairly simple bit of gear so it should not be to difficult to see what the problem is

Regards Don

thx for the info gents!

I will check things out again and will most probably drop the line size

If it has been working for 20 months with that size of line on it reducing the line size should not be necessary to make it work again

I would be looking to see what the actual cause is and as I said earlier it is a fairly simple bit of gear so it should not be to difficult to see what the problem is

Regards Don

May not be the problem but if you have changed a head sail, specifically to a larger one, you need more coils on the drum to furl it, this can cause them to jam up and force them to break because the drum may not have the capacity for the size of rope you are using.

thx for the info gents!

I will check things out again and will most probably drop the line size

If it has been working for 20 months with that size of line on it reducing the line size should not be necessary to make it work again

I would be looking to see what the actual cause is and as I said earlier it is a fairly simple bit of gear so it should not be to difficult to see what the problem is

Regards Don

May not be the problem but if you have changed a head sail, specifically to a larger one, you need more coils on the drum to furl it, this can cause them to jam up and force them to break because the drum may not have the capacity for the size of rope you are using.

Fair enough if a larger sail has been fitted

Regards Don

I would definately do what Don suggested first and stand on the bow and unfurl/ furl the jib to see what is happening before changing the furling line

Just wondered how you ended up with this problem Kean sailor

Ive a Furlex 100s I'm rebuilding (came off an un-sail-able boat) so far the halyard swivel was full of shells Ive given it a basic flush out with clean it tomorrow thoroughly .

Any suggestions as to what grease to use? I am tempted to use spay can of dry lube see how that goes for a start.

Just pulled it apart lots of ball bearings ![]()

![]() which Ill replace Now I can really clean it

which Ill replace Now I can really clean it![]()

27 balls in each race if you ever drop them ![]()

So who are you in love with HG??

Im to old for that Cisco just me boat ![]() who in the h#ll would put up with me

who in the h#ll would put up with me

I bought a tube of furlex grease several years ago. It has a noozle that you can squeeze grease on to the lubrication points on furler. Bit expensive but works well.

Well both bearings are dismantled so my thought is find some teflon grease and repack them

But use it sparingly

I used to have the same problem. Dropped the line size down to 5mm and problem went away.

When deploying the headsail keep some weight on the furling line and cleat it off so that there is very little slack on the drum. When furling keep some tension on the sheets and only furl with hand power. I use a dinghy ratchet block as a turning block. Naturally when leaving the boat make sure you have 3 or 4 wraps of the sheet over the furled sail and the furling line properly cleated off.

Dinghy rachet block as a turning block, thats a great idea!

Hi hg

i serviced my sea furl a couple of years ago

lots of Teflon and steel ball bearings to replace

dry lube,water,no grease

trick to replace is to stick them in races with honey!!

which dissolves with warm water

easy

be wary of greaSe though

my be relevant to you

Cheers

david

Thanks david

I was thinking of using dry lube but the honey has made that solution much better

As far as grease goes if you put to much in when its a real hot day you may end up with grease on your sails